In order to shorten the production process as much as possible and to deliver printing plates of the highest quality, we use a very detailed system of quality assurance.

The process begins during the selection of a printing plate to be produced, as each plate requires appropriate parameters to accommodate the planned flexographic print type. The second step guided by our quality assurance system is the production of printing plates. Finally, the produced plates must be checked, properly prepared for transport, and sent in a timely fashion to the specified address.

The first stage is done in cooperation with the Client; together we check the type, thickness, hardness, and resistance to abrasion and chemicals of the printing plate that we plan to use to print the packaging.

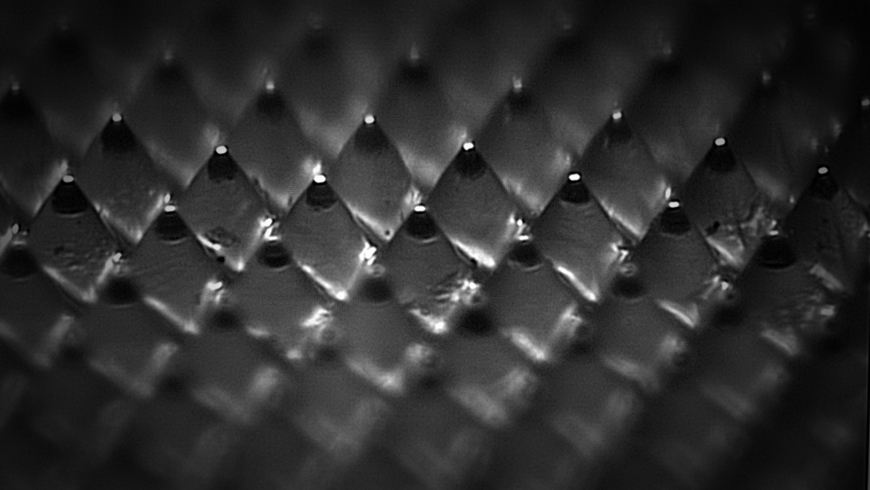

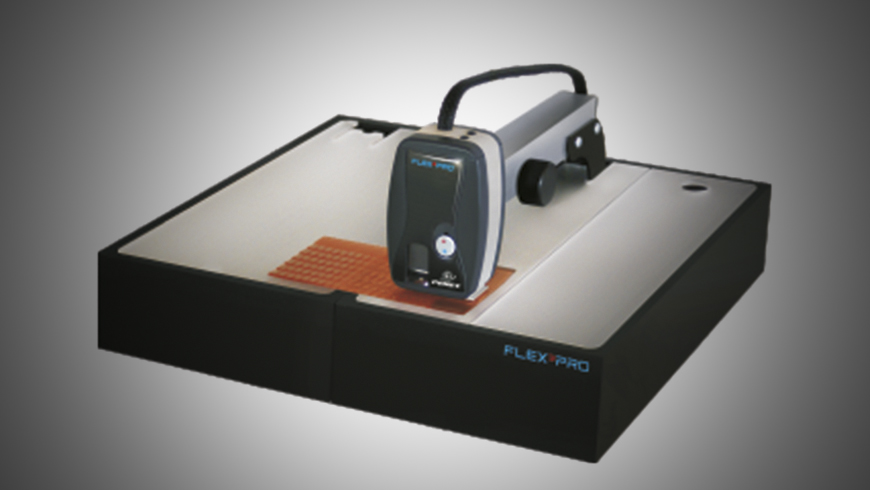

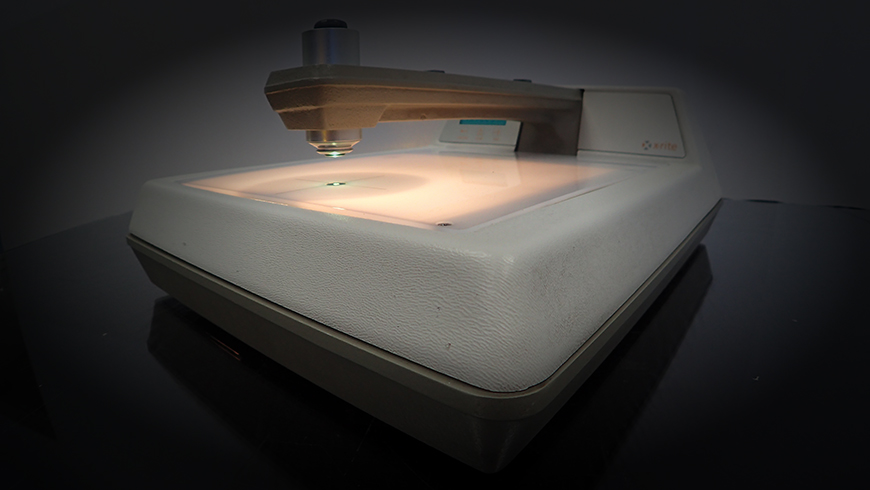

The second stage consists in controlling the durations of printing plate exposure, as well as many other elements specified by our production standards based on tests.

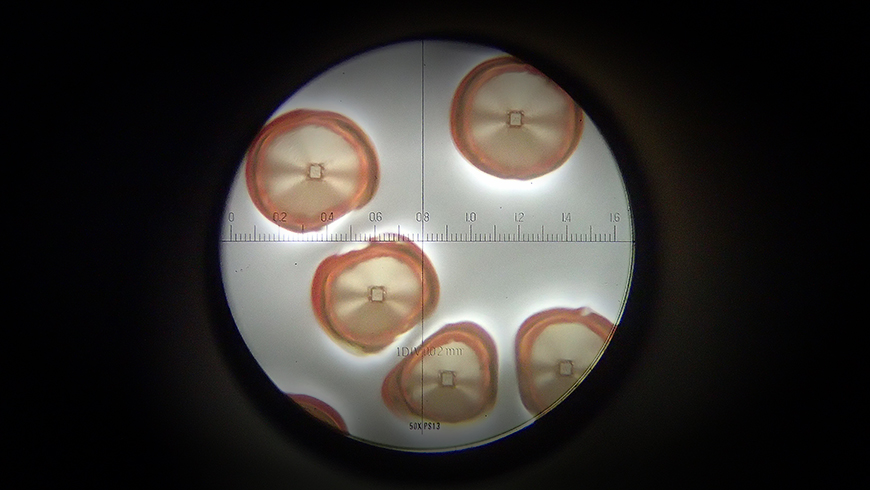

During the third stage, we examine the prepared plates, measuring the height of the relief, checking whether the reproduction conforms with the original, etc. This stage allows us to detect potential defects before sending the plates to the Client.

Finally, appropriate packaging is prepared, the contents of the package go through final checks, and “Printing plate quality certifications” are added as a guarantee for our Clients that our printing plates were manufactured with due diligence and are of the highest quality.

All stages of our quality assurance are constantly being modified to perfect the procedures and adjust them to the changing needs of our Clients.